Part Two - Technical Development

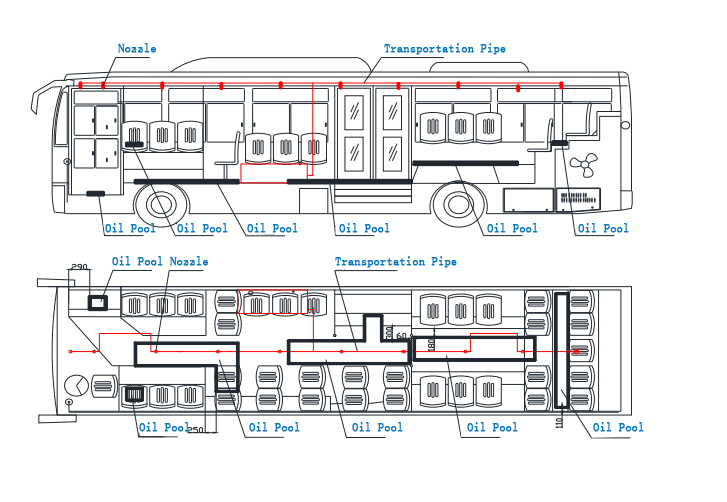

1:Two types of bus compartment fire extinguishing system

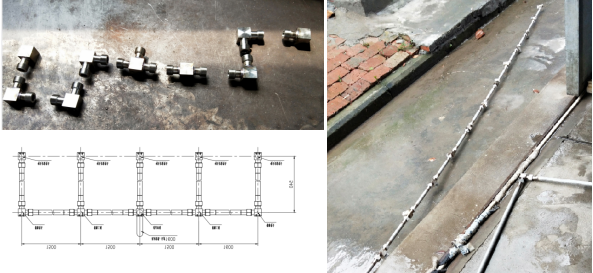

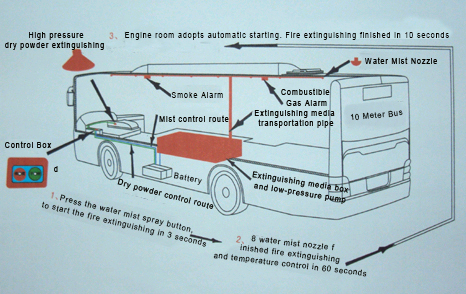

There are pump supplied and cylinder supplied system for bus fire extinguishing system. The first developed system was pump supplied system. The engine room adopted dry powder extinguishing media.

Pump supplied system

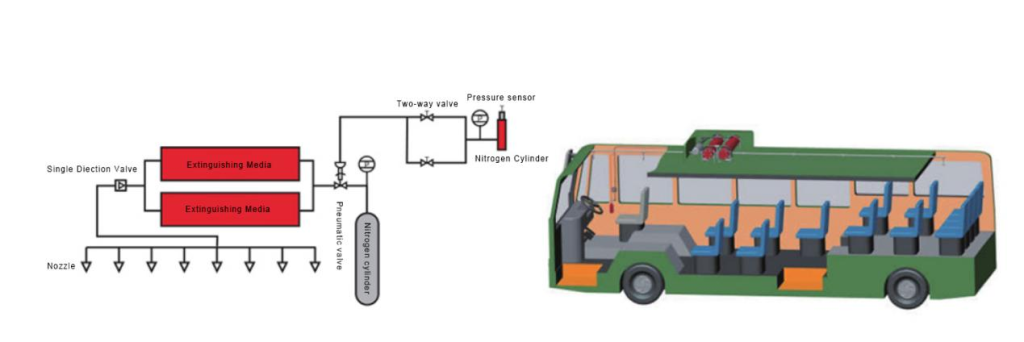

Cylinder supplied system

2:Fire test of bus compartment fire extinguishing system

The very early fire test model was not mature, and gradually after GA1264-2015 was issued, a standard fire test model was formed and widely used.

The very early fire test model

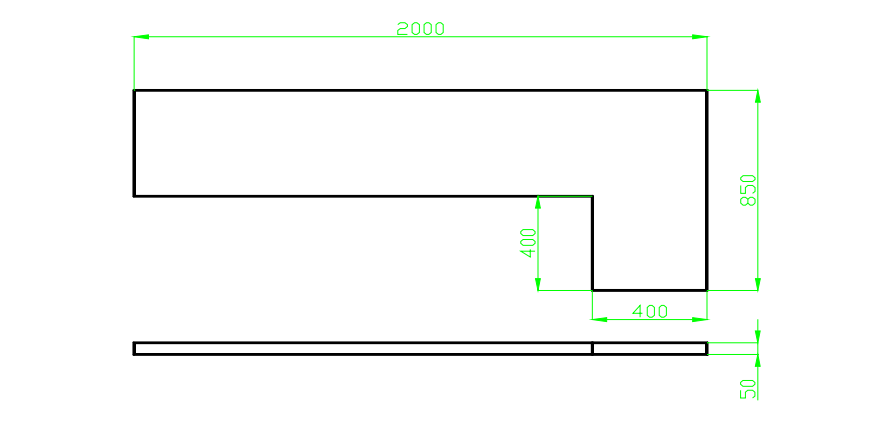

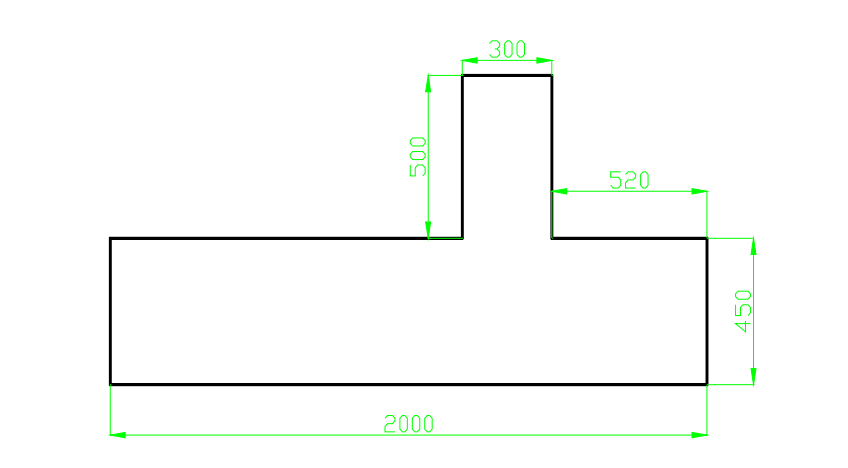

Based on GA1264—2015,fire test arrangement is : Oil pool 1 is “L” shape, Oil pool 2 is “T” shape. And their dimensions are:

Oil pool 1

Oil pool 2

Oil pool 3 dimension: 2000 mm×450 mm×50 mm;Oil pool 4 dimension:2100 mm×350 mm×50 mm;Oil pool 5&6 dimension:300 mm×300 mm×50 mm. Arrangement of the above oil pools shows as follows:

Based on the fire test requirement: Compartment temperature should start to continuously lower down in 10s after the system starts. After 40s, the max. Temperature of the compartment should be lower than +93℃. Naked fire should be extinguished in 60s and the average temperature in the compartment descends to +60 ℃.

Fire Test Video

Other requirements:

- Responding time: less than 4s.

- Spraying time: system should continuously spraying for more than 120s.

- Farthest point pressure: when system is in normal working status, the farthest nozzle working pressure should be within 2Bar to 12Bar.

- Spraying strength: spraying strength should be higher than 2L/min*㎡

3:Other requirements for the system:

- Nozzle:

In low pressure bus compartment fire extinguishing system, the fire extinguishing is co-work of the nozzle and the extinguishing media. Nozzle has taken the responsibility to evenly distribute the extinguishing media in the bus compartment. A qualified nozzle should be able to distribute the extinguishing media droplets evenly and thus can enhance the extinguishing media function. Usually we will do the nozzle water distribution test to test the nozzle application quality.

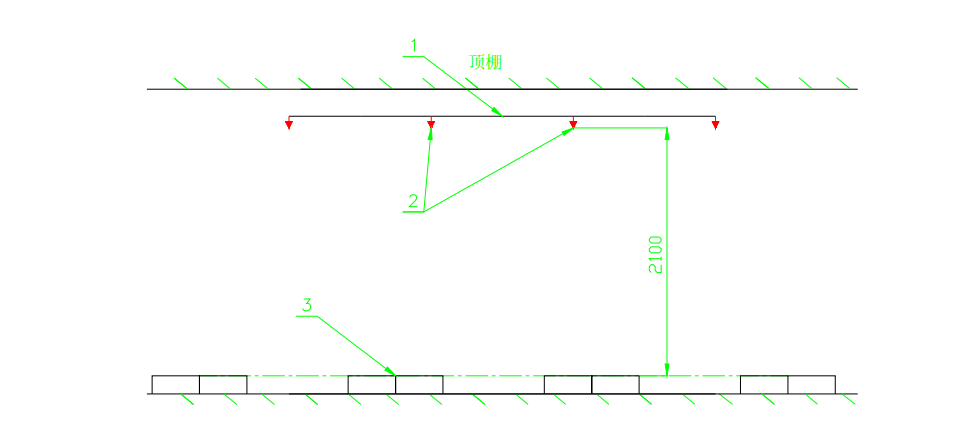

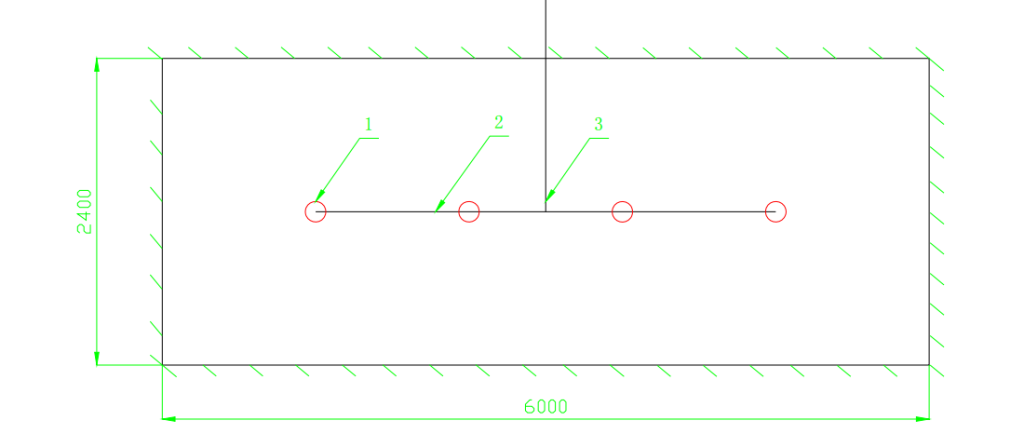

Testing area 2.4 m×6.0 m with arrangement as below figure. The distance from the highest water outlet of the water mist nozzle to the upper edge of the water collecting box is 2.1m, and 4 identical nozzles are symmetrically arranged on the test pipe network. Nozzle spacing is 1.2 m.

- Pipe

- Nozzle

- Water collection box

- Nozzle

- Steel pipe: Dia. 20mm

- Steel pipe: Dia 32mm

90 water collecting boxes with an area of 0.4 m × 0.4 m will be evenly arranged in the protection area of 4 nozzles, the flow rate of each water mist nozzle should be the flow rate calculated by the formula Q=K. The watering time of the test shall not be less than 3 min.

Nozzles are installed with 1.2m-1.5m distance from each other. Usually for a 12m bus, there wIll be 10 pcs of nozzle. Nozzles are usually installed in the middle of the passage to ensure a even distribution of droplets to the two sides of the bus compartment.

Lanzhong is the earliest developer and sole manufacturer of mature low pressure water mist nozzles for Chinese Bus Compartment Fire Extinguishing System. In 2016, Our engineer team co-worked with our customer and successfully developed Chinese first low-pressure water mist fire extinguishing system for bus compartment according to the standard.

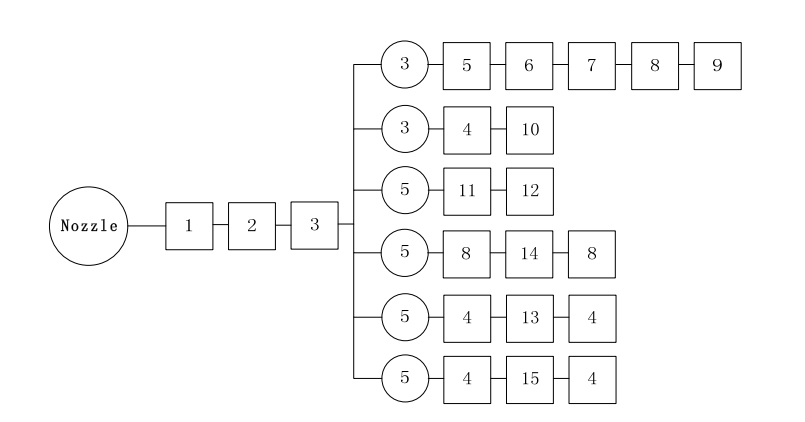

All low pressure water mist nozzles are under strict test:

Note:

Number in the “□” represents test procedure sequences.

Number in the”○” represents test nozzle quantity.

Test procedure sequence:

- Material

- Appearance

- Filter

- K factor

- Spray angle

- Spray ability

- Water distribution ability

- Strength

- Low-temperature test

- High-temperature test

- Vibration test

- Mechanical impact test

- Salt spray test

- stress corrosion cracking test in ammonia

- Sulfur dioxide corrosion test

- Pipe

The piping layout of the system shall not affect the aesthetics of the cabin, and the parts used for fixing the piping shall be treated with anti-corrosion. The maximum distance between fixed points of system piping shall comply with the provisions in below Table.The pipe network layout of the system should adopt a balanced system.

| Nominal Dia/mm | ≤25 | 25 | 32 | 40 |

| Max. Distance/m | 1.0 | 1.2 | 1.4 | 1.6 |

Normally there are two types of pipe connections:

- Brass fast connection pipe

- Union connection pipe